Analysis of the latest supply chain shocks and how to mitigate

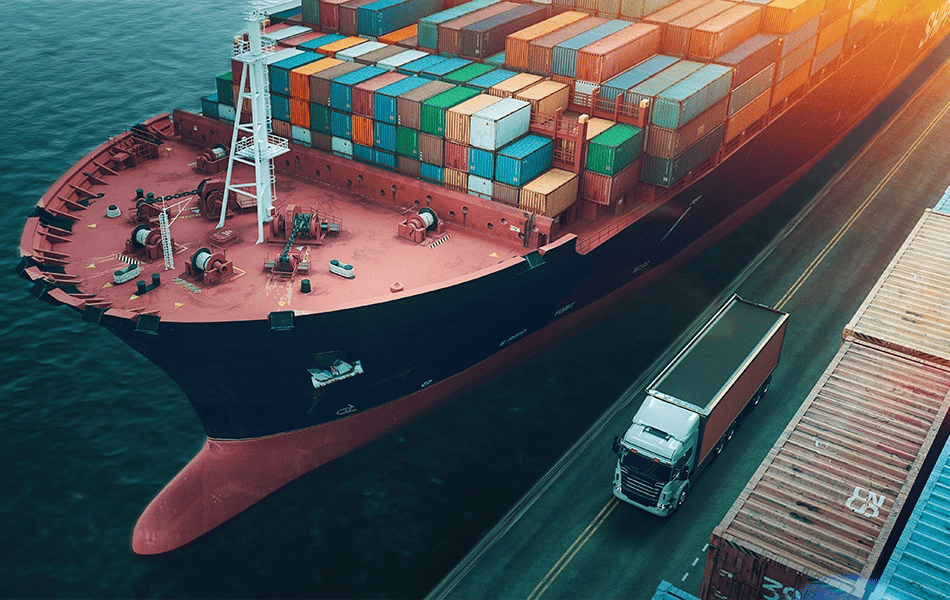

During and after the COVID-19 pandemic, the global supply chain faced unprecedented disruptions, highlighting the need for resilience and adaptability. The supply chain landscape experienced a chaotic time as shortages, inflation and delays in supply became the norm. Furthermore, increased volatility in both demand and supply created a pressing need for supply chain management to overcome these challenges. In addition to these immediate concerns, the demand for sustainability has emerged as a significant driver, demanding transparency and accountability throughout the supply chain.

This article examines the current challenges faced by supply chain management and explores potential strategies to mitigate supply chain risks. It is a summary of episode 5 of the retail webinar series, Supply Chain Challenges, hosted by Director of Industry, Brian Cluster, in conversation with Dr. Daniel Lin, University of San Diego, and Ajay Bohra, working as a consultant with the Ocado Group.

Ocado is a British solution provider for online retail businesses and is leveraging a combined product, location and supplier data solution from Stibo Systems.

There are several imminent challenges in supply chain management that retailers need to address, including shortage of talent and labor, inflation and demand volatility.

The scarcity of skilled talent and labor is impeding the optimization of operations. Challenges related to inflation and delays in the availability of goods are impacting pricing and the accommodation of consumer expectations. Additionally, the increasingly volatile market demand requires agile supply chain strategies to ensure prompt responsiveness.

Sustainability demands pressuring supply chains

A major factor, which is currently transforming supply chain management, is the demand for sustainability which is pushing organizations to adopt responsible practices. Two primary drivers behind this shift include:

The first driver is consumer demand: Modern consumers seek more than just product availability and competitive pricing. They demand transparency regarding the origins and production processes of the goods they purchase. This shift in consumer behavior compels retailers to provide the story behind their products.

The second driver is compliance and regulation: Stringent regulations, such as the Lacey Act, mandate that companies using natural resources must ensure transparency in their supply chains. To comply, organizations must have a thorough understanding of the origin and authenticity of the resources they use.

Creating supply chain transparency

To meet sustainability demands and comply with regulations, supply chain transparency has become imperative. It involves gaining visibility into not only the first-tier suppliers but also the second, third and so forth. Several approaches can be employed to achieve supply chain transparency:

-

Blockchain technology

Leveraging blockchain can provide an immutable record of a product's provenance, allowing stakeholders to trace its journey through the supply chain. This technology enables enhanced transparency and accountability. -

Shortening the supply chain

Reducing the number of intermediaries in the supply chain minimizes complexity, improves responsiveness and enhances control over sourcing and production processes. -

Data analysis

Effective utilization of data analysis tools can provide valuable insights into the supply chain. Companies must develop the capability to collect, analyze and interpret data to optimize their operations effectively.

WHITE PAPER

Achieving Supply Chain Transparency

Learn more about supply chain transparency, why it is important, and how to achieve it with Stibo Systems Supplier Data Cloud.

The future of supply chain management

To mitigate supply chain risks, retailers are actively adopting strategies that prioritize resilience and efficiency:

Diversification into a supply network

Retailers are transitioning from a linear supply chain model to a supply network, facilitating better detection of bottlenecks and managing consumer expectations. This involves establishing stronger partnerships with suppliers, creating their own brands and renegotiating service level agreements (SLAs).

Building predictive models

Retailers are leveraging predictive analytics and analyzing public data to forecast potential shortages. By proactively identifying risks, companies can take preemptive measures to mitigate disruptions.

Automation and robotic process automation (RPA)

Automation is playing a pivotal role in optimizing supply chain operations. Retailers are increasingly employing automation and RPA for picking and packing and streamlining repetitive tasks, ensuring efficiency while compensating for labor shortages. This shift allows organizations to re-allocate employees to focus on higher-value tasks, leveraging their skills and expertise.

Building data literacy

As data becomes increasingly important in supply chain management, retailers must prioritize building data literacy within their organizations. This does not necessarily mean that everyone must be a data analyst, but everyone must understand the importance of data and of being a data-driven company. Retailers already have access to vast amounts of data that is either generated in their supply chain or impacts their supply chain operations, such as shipping delays or freight rates.

By harnessing the power of data, retailers can make informed decisions, drive innovation and build more resilient supply chains.

EXPLORE

Supplier Data Cloud